Anti-static Garments: Outstanding Protection from Yarn to Garment

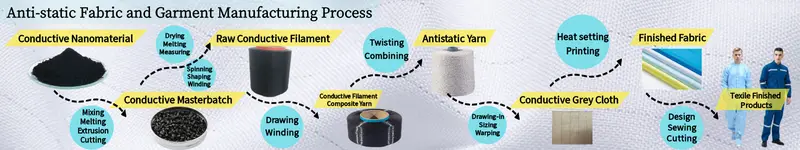

In modern industrial environments, managing electrostatic discharge (ESD) is essential to prevent damage to sensitive equipment, protect workers, and maintain operational efficiency. Antistatic garments provide crucial protection against electrostatic buildup, and our comprehensive industrial chain ensures a seamless journey from yarn production to finished workwear, delivering optimal solutions for diverse sectors.

1. Innovative Yarn Manufacturing for Effective Conductivity

As a leading producer of functional clothing, we begin with the core component: specialized yarns. These yarns are designed to exhibit exceptional conductive properties, which are critical for effective electrostatic discharge protection. The conductive fibers are meticulously engineered using advanced materials to ensure consistent conductivity, even under varying environmental conditions.

2. Advanced Fabric Production for Durability and Comfort

After yarn production, the next step is transforming the yarn into fabric using cutting-edge textile technologies. Our production process intricately weaves conductive yarns with other fibers to create a fabric that is both antistatic and comfortable to wear. This textile structure not only discharges static electricity effectively but also maintains breathability, durability, and comfort, even in demanding work environments.

To ensure precision in fabric quality, we utilize top-tier machinery sourced from industry leaders. This enables us to carefully control key factors such as fabric thickness, density, and strength, ensuring that our products meet the highest standards of performance and reliability.

3. From Fabric to Workwear: Precision and Performance

Our design team ensures that the workwear meets the functional demands of various work scenarios while allowing wearers to move freely. Each piece of antistatic workwear undergoes meticulous processes, including precise cutting, expert sewing, and rigorous quality inspections. We pay close attention to every detail, employing specialized sewing techniques to minimize the risk of static electricity generated by seam friction.

With the advantage of a complete industrial chain, CJTI is able to ensure the stability and consistency of product quality. We continuously invest in R&D resources and collaborate with research institutions to explore innovative applications of antistatic technology to meet the increasingly stringent industry standards and customer demands.